Webzine

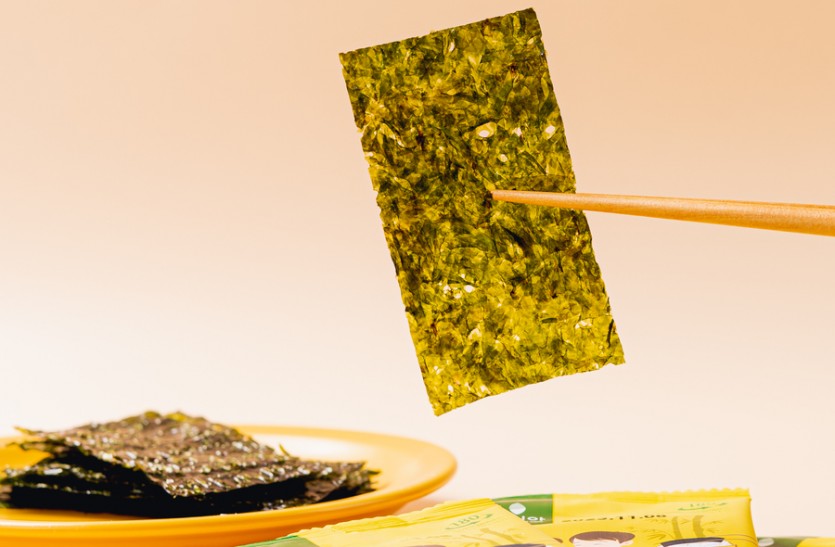

From the Sea to the Table… “Bamboo Salt Laver Made with Organic Seaweed”

2025.09.08Visiting Nenia’s Production Sites – (Kwangcheon Kim Co., Ltd.)

Korea, a Global Leader in the Seaweed Market

Seaweed (laver) is a uniquely positioned food, as only three countries—Korea, China, and Japan—produce, process, and sell it on a commercial scale. While Taiwan, North Korea, and New Zealand also produce seaweed, their volumes are so small that they are not even reflected in global statistics. Thailand, on the other hand, does not produce its own seaweed but imports and then processes and sells it.

China ranks first in global production, but most of what it harvests is consumed domestically. By contrast, Korea is number one in seaweed export value and global market share. According to the Ministry of Oceans and Fisheries, Korea’s seaweed exports in 2024 reached an all-time high of USD 997 million (about KRW 1.3 trillion). This accounts for roughly one-third of Korea’s total seafood export value, which stood at USD 3.03 billion.

The Korean government is actively fostering seaweed as a strategic export item, and has also put in place a well-structured export certification system.

Nenia pursues naturally derived ingredients to create products that are both safe and of the highest quality. For the June issue of the Nenia Web Magazine, we visited the production site of Kwangcheon Kim Co., Ltd., Nenia’s partner in manufacturing “Bamboo Salt Laver Made with Organic Seaweed,” to uncover and share the story behind the scenes.

Kwangcheon Kim: Driving Thousands of Kilometers Each Dawn in Search of the Best Seaweed

Which company exports the most laver in Korea? The answer is Kwangcheon Kim Co., Ltd., located in Gwangcheon-eup, Hongseong County, Chungnam Province. The company takes its name from this very region, “Gwangcheon.”

Gwangcheon became famous for laver due to a combination of geographical, historical, and industrial factors. Situated along Korea’s west coast, it has a large tidal range and well-developed mudflats—ideal conditions for cultivating raw seaweed. In fact, seaweed was historically harvested in areas very close to Hongseong.

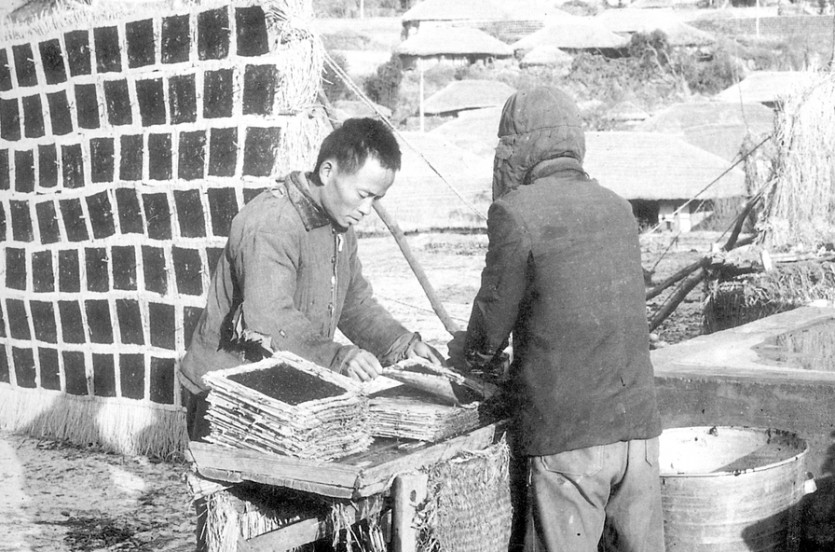

Another reason for Gwangcheon’s reputation lies in its long history as a major distribution hub for laver. Since the Joseon Dynasty, seaweed production was active in the southern and western seas, where it was first dried into sheets before being shipped to Gwangcheon for distribution. The founder of Kwangcheon Kim himself began in this trade, supplying dried seaweed at the local markets. Today, more than 1,000 companies in Korea are involved in seaweed processing, and as seasoned laver products (flavored and roasted) have grown in popularity, many processing firms have clustered in the Gwangcheon area. This is why countless businesses use the name “Gwangcheon Kim” as a kind of nickname, even though their company names differ.

The founder of Kwangcheon Kim Co., Ltd., Mr. Bokman Kim, was born in Gwangcheon-eup. In 1970, he launched Baekje Trading Company in Gwangcheon and began the dried seaweed distribution business, while also serving as the head of the Boryeong Fisheries Cooperative at the time.

In 1998, his son Jaeyu Kim (now Senior Advisor at Kwangcheon Kim), then just 28 years old, established Baekje Foods and started producing seasoned laver. In the early days, Advisor Kim and his wife made and sold seasoned laver together, loading up a one-ton truck and driving all the way to Gangwon Province to sell their products. They often worked while sleeping only three to four hours a night. That small family business grew, and in 2008 it was renamed Kwangcheon Kim Co., Ltd.. As of May 2025, it has grown into a mid-sized company with 900 employees.

The company’s strength lies in its commitment to using only the highest-quality raw seaweed. Kwangcheon Kim holds the largest share of raw seaweed in Korea, purchasing and carefully selecting around 10 million “sok” annually from production sites. (One “sok” is a unit equivalent to 100 sheets of dried laver.) Even when processed under the same conditions, dried laver differs in taste and quality depending on the batch of raw seaweed. To secure the best raw materials, Advisor Jaeyu Kim personally inspects and purchases raw seaweed at the markets each dawn. He drives thousands of kilometers every day, ranging from Korea’s west coast all the way down to Haenam at the southern tip of the peninsula.

This hands-on procurement approach reflects more than just a business routine—it symbolizes the company’s philosophy of insisting on the finest raw materials. In a market with more than 1,000 competing seaweed processors, Kwangcheon Kim’s near hand-selected sourcing is the key to ensuring consistently top-quality products and serves as its most decisive competitive edge. Thanks to this philosophy—along with its efficient production and distribution system—Kwangcheon Kim has grown into a global company that supplies not only the domestic market (major corporations, large retailers, and online marketplaces) but also exports to over 50 countries worldwide. Seongmun Heo, Director and Head of Sales at Kwangcheon Kim Co., Ltd., elaborated on what makes Kwangcheon Kim truly unique.

The Life of Seaweed: “Time is Everything—It Must Be Dried Within 40 Hours”

Seaweed farming begins around May to June, when spores are attached to seedling nets (mesh lines). These are then set into the sea, where the seaweed begins to grow under natural sunlight. Harvest season for raw seaweed (mul-gim) typically runs from October through the following May. Once harvested, fishermen auction off their catch at local fishery markets. Manufacturers then purchase the raw seaweed and process it into dried laver in the first stage of production. This dried laver is either distributed directly or undergoes secondary processing, where it is transformed into products such as roasted laver or seasoned laver.

△ Production site at Kwangcheon Kim Co., Ltd. Workers sorting out foreign substances before processing dried laver. (Photo = Nenia)

Once raw seaweed (mul-gim) is harvested from the sea, it becomes a race against time. If it isn’t processed into dried laver within 40 hours, it will spoil. At times, when there aren’t enough primary processors to handle the raw seaweed, some of it ends up being discarded. Seaweed is harvested only once a year.

Seaweed farming methods are broadly divided into fixed-pole (jiju-sik) and floating (buyu-sik) cultivation. The fixed-pole method is often referred to as the traditional way, but these days the distinction matters less. In fact, floating cultivation now accounts for the majority, as it produces much higher yields—the ratio is about 20% fixed-pole to 80% floating.

Nenia’s “Bamboo Salt Laver Made with Organic Seaweed” uses laver from floating cultivation, while its “Organic Stone Laver Flakes” are made from laver harvested through fixed-pole cultivation. Stone laver (dol-gim) refers to seaweed that grows attached directly to rocks and is harvested by hand. Collecting stone laver is risky work, as harvesters must secure themselves with ropes while climbing between rocks along the shore.

Why Nenia’s Bamboo Salt Laver Is Special:

The Rare World of Organic Laver

Nenia Bamboo Salt Laver Made with Organic Seaweed is a certified organic processed food. It is made with organic seaweed grown in Korean coastal waters, carefully dried, and combined with domestic bamboo salt and organic canola oil. Likewise, Nenia Organic Stone Laver Flakes use certified organic stone laver harvested from Korean seas, with the addition of domestic sesame seeds and domestic perilla oil for a rich, nutty flavor.

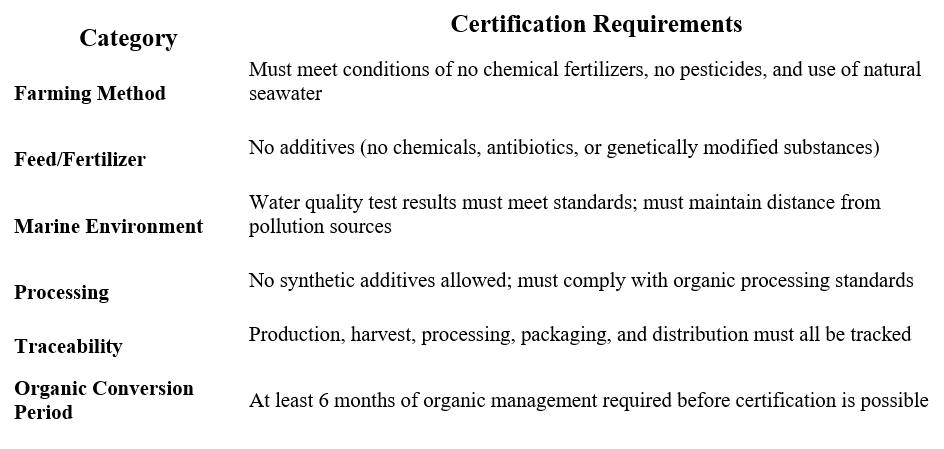

You might wonder: How can organic-certified waters be distinguished from ordinary ones, when seawater inevitably mixes? How is that distinction guaranteed?

To produce certified organic laver, the Ministry of Oceans and Fisheries must first designate the farming area as an organic-certified sea zone. Pollutants cannot be discharged near the farm, and organic-certified waters are kept significantly separated from general fishing zones. Not only the sea but also the surrounding land environment must be managed.

The process doesn’t end there. Raw seaweed harvested from an “organic-certified sea zone” must itself receive organic certification before it can be processed into dried laver, and only then can the final product bear the organic certification mark. For laver to qualify as truly “organic-certified,” the sea zone, the primary processing plant, and the secondary processing plant must all undergo certification. These certifications are integrated and issued by the National Fishery Products Quality Management Service. With such strict oversight, organic laver is regarded not just as special but as truly precious.

Unlike conventional laver, organic laver is never acid-treated (a chemical activation process). Pesticides and chemicals also cannot be used to control pests or disease, which means production requires far more time and cost. It’s estimated that only about 10% of all laver produced in Korea qualifies as organic.

According to Seongmun Heo, Director of Sales at Kwangcheon Kim Co., Ltd., “Producing organic laver requires tremendous effort, and there are very few companies like Nenia that deal exclusively in organic laver.” He also explained that “dosirak-gim” (seasoned laver for lunchboxes) is a uniquely Korean brand category. While Koreans typically enjoy seasoned laver as a side dish with rice, overseas consumers often find it displayed in supermarket snack aisles and eat it more like chips.

[Table 1] Certification Requirements

Solar Panels on Factory Roofs and Electric Vehicles: Responding to the Climate Crisis

Seaweed harvested from the southern coastal regions—Jindo, Wando, Shinan, and Goheung—is typically used for gimbap laver. By contrast, laver from Korea’s west coast is known as “jaerae-gim” (traditional laver) and is considered ideal for making seasoned laver (dosirak-gim).

The optimal temperature range for seaweed growth is 5–15°C. Germination occurs at 15–22°C, and seed implantation at around 22°C. However, due to the effects of the climate crisis, rising sea temperatures have delayed the seeding season. Traditionally, raw laver (mul-gim) is harvested beginning in October, but in 2024 the harvest did not begin in earnest until November.

Seongmun Heo, Sales Director of Kwangcheon Kim Co., Ltd., admitted that although he had never formally studied climate change or environmental issues, working with seaweed made him naturally concerned about the climate crisis, given how sensitive the crop is to water temperature and environmental shifts.

In response, Kwangcheon Kim has installed solar panels on the roofs of all its factories and uses electric vehicles for transportation between facilities. Still, the company notes that the electricity generated is nowhere near enough to cover all its energy needs with renewable sources.

A Special Partnership: Nenia and Kwangcheon Kim

Director Seongmun Heo remarked, “Our focus is on making delicious laver.” The management philosophy of Kwangcheon Kim Co., Ltd. is built on three pillars: “the finest raw materials, the optimal production environment, and a spirit of utmost customer satisfaction.” Heo added, “Our founder and current president often remind us that food must be delicious—there’s no point in making it with inferior ingredients or cutting corners.”

Though this may sound like the simplest of philosophies, in reality many companies fail to live up to it.

Nenia is dedicated to researching, developing, and supplying safe and delicious products made with organic ingredients, while Kwangcheon Kim commits its efforts to sourcing top-quality raw seaweed and applying advanced processing techniques. Together, they create a strong synergy, ensuring that consumers can enjoy laver products that are both safe and exceptional in taste. True to its principles, Nenia never uses any synthetic chemical additives in its products.

[Table 2] Features of Nenia Bamboo Salt Laver and Organic Stone Laver Flakes

1. 100% Certified Organic Seaweed Made only with domestic organic seaweed, so you can enjoy it with confidence. Cultivated in pristine waters without chemical fertilizers, antibiotics, or pesticides. Seasoned with organic sugar and domestic bamboo salt for a subtle, savory flavor. 2. Additive-Free Processing No synthetic flavorings, seasonings, or preservatives. Preserves the pure taste and aroma of natural seaweed. 3. Rich, Nutty Flavor Offers the deep umami of organic seaweed and a crisp, satisfying texture. Perfect as a light snack, a side dish with rice, or an ingredient for gimbap. 4. Clean and Safe Production Process Processed in HACCP-certified sanitary facilities. Strict quality control at every stage: washing → drying → roasting → packaging. |

Through our visit to Kwangcheon Kim Co., Ltd., we confirmed that Nenia’s Bamboo Salt Laver Made with Organic Seaweed and Organic Stone Laver Flakes are precious products, born from Korea’s clean seas, subjected to rigorous organic certification, and crafted with the tradition and artisanal commitment to quality that define true excellence.

Nenia Web Magazine Editorial Team

June 10, 2025